3-in-1 Automatic color steel glazed roof tile metal forming machine

To meet the requirements for roll forming two different profiles in a limited plant area with quick product changeover, ZHONGHENG have various kinds of double layer roll forming machine.

The machine have alternating bottom and upper stands. Rolls for one profile( like ibr sheeting ) are installed in the bottom stands, and rolls for another profile(like corrugated sheeting )are mounted on the upper stands. The whole line will use only one uncoiler, one cutoff unit, one controlled box. But the machine can't produce the 2 profiles at the same time.

Main Features of Double Layer Roof Sheet Roll Forming Machine

1.Produce different roof panel size in one machine

2.Save space, more convenient

3.Easy operation,low maintenance cost

4.Stable and durable,sea freight for import can be saved bt 50%

Product Paramenters

(1). Brief Introduction

The Roof tiles made by our metal corrugated roof sheet making machine have beautiful appearance and bright color.

They are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands,ancient architectures and modern villas.

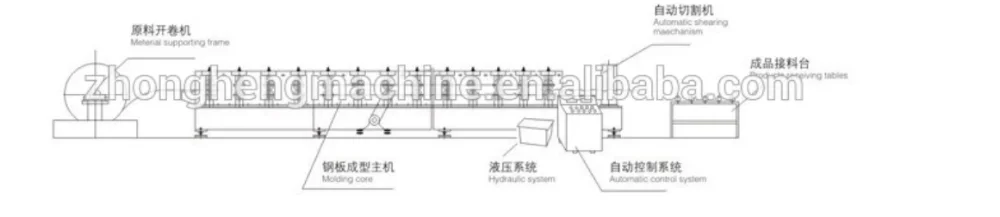

2).Working Flow of 3-in-1 Automatic color steel glazed roof tile metal forming machine

Decoiling the sheet-Sheet guiding-Roll forming-Measure length-Cutting the panel-Panels to the supporter

(3).Technical Detail

A Sheet Specifications

1 | Coil Type | PPGI GI |

2 | Width | 1200mm |

3 | Thickness | 0.3-0.8mm |

4 | Yield stress | Q235 |

5 | Effective | 900mm |

B Components Details

Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

Main Frame | 350#steel.More stable and no shaking |

Middle Plate | 16mm. We use thicker plates to ensure stability of our products. |

Forming Steps | 15, according to the drawing. |

Shaft Material | Φ70 mm, high grade 45# steel. |

Treating process: tempering- finish turning,

high rigidity, hard to deform. |

Cutting Blade Material | Cr12, hardness HRC60-62. |

Treating process: heat treatment- plane abrasion- wire electrode cutting. |

Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

Screen | 7 inch touch screen, easy to operate. |

PLC | Delta DVP 14ES |

well-adapted to various conditions, such as moisture,

electromagnetic disturbance. |

| Delta VFD-M. It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

Length

Measurement Device | Omron, made in Japan. |

It features with high accuracy and stability. |

More pictures for your reference

Trade Terms

1.Payment Term:30% paid by T/T as down payment,Balance 70% after inspection before delivery. After finish production, we will inspect the machine and inform the buyer, the buyer come inspect goods, then pay the balance before shipping.

2.Delivery Time:We guarantees the equipment will be ready for shipment within 30 working days after receipt of deposit .

3.Port of Loading: Tianjin

After sale service

1.Warranty: We provide one year free warranty , and technical support for entire life .

During the warranty, the replaceable parts are free,buyers need to pay for the shipping .We will also provide you instruction manual to show you how to operate the machines.

2.Installation and trainning:We could send technician to your country to install machine if you need. The buyer need to pay extra cost, including:visa, round trip tickets, accommodation, salary of USD 100~120 per day.

Contact us for more information about roll forming machine and slitting line .